non contact metal thickness measurement|novacam thickness chart : discounter Paste thickness measurement after metal masking. More details. NEW. Reflective. Film coating thickness measurement in explosion-proof environments. More details. Thickness is measured by passing a target between two sensors. A newly designed optical system and dedicated jig allow for ultra-stable thickness measurement that is resistant to . MarjoSports: A melhor casa de apostas do mundo e com as .

{plog:ftitle_list}

20 de jun. de 2022 · We’ll send you a $5 coupon to use on Sisu products when you enter your email address! (popup) Reply; Reply with quote; 2 replies. Jun 21st, 2022 5:52 am #2; savemoresaveoften Deal Addict May 3, 2008 3175 posts .

Advantages of non-contact measurement with displacement sensors include their non-destructive technique, ability for single-sided continuous thickness measurement, ability to cope with coatings, linings, etc., and high accuracy (0.1 mm and less) using standard timing .Get reliable, online thickness measurement of aluminum and aluminum alloys with non-contact gauges specially designed to provide accurate readings, regardless of the alloy chemical composition or cladding layers in cold strip .Paste thickness measurement after metal masking. More details. NEW. Reflective. Film coating thickness measurement in explosion-proof environments. More details. Thickness is measured by passing a target between two sensors. A newly designed optical system and dedicated jig allow for ultra-stable thickness measurement that is resistant to . The results of this paper revealed that online thickness measurement systems could be developed for various advanced industrial applications. A simple method for measuring the thickness of metal films based on eddy-current sensors (ECSs) immune to distance variation is proposed. The slope of the lift-off curve (LOC) in the RL impedance plane is a good feature .

The stainless steel roller represents the reference system for the measurement. Thickness measurement of flat film. Oil film thickness. . Layer thickness measurement belongs to the group of one-sided, non-contact thickness . A simple method for measuring the thickness of metal films based on eddy-current sensors (ECSs) immune to distance variation is proposed. The slope of the lift-off curve (LOC) in the RL impedance .

Non-contact ultrasonic instruments; Metal-notched gages. These tools manually determine thickness when hand-dragged through the applied powder. Similar to how a wet film gage works, the device determines powder height as being between the highest numbered tooth that made a mark and has powder clinging to it, and the next highest tooth that .Non-destructive, contact-free measuring possible; More about the phase-sensitive eddy current method. Duplex coating measurement. . Universal instrument for metal and precious metal analysis as well as coating thickness measurement .This paper proposes an online, non-contact metal film thickness measurement system based on eddy current sensing. The slope of the lift-off curve (LOC) is used for characterizing target thickness. Theoretical derivation was conducted to prove that the slope is independent of the lift-off variation. In practice, the measurement has some immunity .

How do you measure metal thickness? To accurately measure the thickness of a metal without damaging it, an ultrasonic thickness gauge should be used. What is mil thickness? A mil (or thou) is a unit of thickness that equals one thousandth of an inch (0.001 inches). Example: 10 mils = 0.010 inches. Can Non-destructive Methods Be Used to Measure Sheet Metal Thickness? Non-destructive testing (NDT) techniques are widely used in various industries for quality control purposes without causing any damage to the material being tested. . Optical measurement devices are non-contact and can provide highly accurate measurements with minimal risk .

Whether your application is steel, aluminum, plastics, lithium-ion battery, or nonwovens manufacturing, our time-tested non-contact thickness measurement and coating weight gauges provide robust, reliable, accurate, and repeatable measurements and controls—helping to ensure your products meet the most precise specifications.The EddyCus® lab 2020 Series allows manual single point measurements of conductive thin films and layer thickness measurement of thin metal layers in non-contact mode.The compact bench-top device is ideal for fast and accurate measurements of samples up to 200 x 200 mm² (8 x 8 inches). In addition to the measurement of thin conductive layers also doped wafers and . Examples of Non-Contact Measurement Use Cases: Electronics Manufacturing: Measuring the dimensions of printed circuit boards (PCBs) and ensuring the correct placement of components without damaging the sensitive parts.; Medical Devices: Inspecting delicate surgical instruments, implants, or stents where physical contact could affect sterility or cause damage.

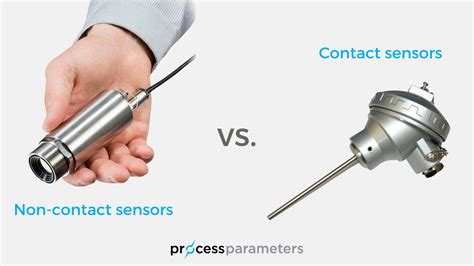

Request PDF | Non-contact thickness measurement for ultra-thin metal foils with differential white light interferometry | A new differential white light interference technique for the thickness .NOVACAM TM 3D metrology systems deliver fast and reliable non-contact thickness measurements of transparent and semi-transparent materials. They offer: Precision better than 1 µm; Thickness measurements of thin films, single-layer films, or multi-layer films; Films and film stacks: from 10 µm to several mm thick. The systems simultaneously measure the thickness . Thickness measurement is an important step in production monitoring, quality assurance and machine control. Although thickness measurements can be carried out using contact or non-contact sensors, .

Measuring Metal Thickness. March 31, 2016 Updated on: July 30, 2024 by: IMS . Contact Us. Informational Guide. Time to Read: 1 m 27s. In today’s metal industry, gauge and inch measurements are both used to describe thickness. . Meanwhile, the Brown and Sharpe Gauge is used to measure brass, aluminum, and other non-ferrous metals. Measuring .Metal thickness: 2 nm – 2 mm (depending material conductivity) Resistivity: 0.1 mOhm cm – 1 ohm cm; Residual moisture (measurement in wet layers by non-contact permittivity measurement) Electrical anisotropy: 0.33 to 3 (higher on . This paper proposes an online, non-contact metal film thickness measurement system based on eddy current sensing. The slope of the lift-off curve (LOC) is used for characterizing target thickness. Laser thickness measurement is a non-contact technique used to measure the thickness of various materials such as metals, plastics, rubber, textiles, and paper. The technique involves the use of a laser to measure the distance between the surface of the material and a reference point, which can be used to calculate the thickness of the material.

The eddy-current method has been employed to realize the real-time measurement of thickness distribution and polishing endpoint detection of metal films during the metal chemical mechanical polishing (CMP) process. However, accuracy and sensitivity in thickness measurement can be significantly impacted by a variation in lift-off distance (about .

The requirements for the non-contact, highly precise online thickness measurement of metal films have rapidly increased with the development of industrial automation, semiconductor industry, and micromechanical technology. Researchers have proposed various non-contact methods for different measurement ranges, such as eddy current,9–17 X- Organic powder over metal or MDF and powder enamel over metal are common applications, and it is possible to measure thicknesses of 1,000 microns or higher. . One of the unique aspects of the ATO technology used in the Coatmaster compared to approaches of other systems used for non-contact film thickness measurement is the implementation .

Virtually any common engineering material can be measured ultrasonically. Ultrasonic thickness gauges can be set up for metals, plastics, composites, fiberglass, ceramics, and glass. On-line or in-process measurement of extruded plastics and rolled metal is often possible, as is measurement of individual layers or coatings in multilayer .Thermo Scientific non-contact metal thickness and coating weight gauges provide real-time measurements of flat metals while maximizing raw material use. . Whether your application is steel, aluminum or non-ferrous, our non-contact thickness measurement and coating weight gauges provide precise, real-time measurements—helping to optimize . An online, non-contact metal film thickness measurement system based on eddy current sensing demonstrated significant advantages, such as simple and clear conversion between the slope of LOC and target thickness, high resolution and stability, and minimized effect of lift-off variation. This paper proposes an online, non-contact metal film thickness .

types of non contact sensors

Object moved to here. A similar non-contact online thickness measurement system based on the eddy current sensing is proposed that uses the slope of the lift-off curve to determine the target thickness . Yang Y, Kang Z, Zhihua F (2017) A thickness measurement system for metal films based on eddy current method with phase detection. IEEE Trans Ind Electron 64(5 .

single yarn strength tester manufacturers supplier

single yarn strength tester pdf supplier

web15 de set. de 2023 · The simplest way to get started is to use the ElevenLabs free speech AI tool. To use this, go to beta.elevenlabs.io and create an account (you can use your own email, a Google account, or .

non contact metal thickness measurement|novacam thickness chart